What V-Model Really Means in Automotive Systems Engineering

What V-Model Really Means in Automotive Systems Engineering

Introduction: Why V-Model Is So Often Misunderstood

Generally, in systems engineering discussions, the V-Model is widely misunderstood. Furthermore, many treat it as just another schedule—a tidy diagram to insert into a project plan. However, that view strips it of both philosophical depth and practical power.

Therefore, the V-Model is not a timeline; it serves as a commitment map. Moreover, each step down the left side defines an obligation, and teams later test each one on the right.

Consequently, when applied correctly in the automotive industry, the V-Model helps prevent design drift, align multidisciplinary teams, and create a direct connection between requirements and validation. Unfortunately, many organizations still use it mechanically, missing the true intent.

Hence, this article demystifies the V-Model by reframing it as a philosophical and operational tool. Additionally, it introduces the concept that the V-Model is about aligning purpose, process, and proof—and sets the stage for understanding how Objectivist principles clarify its power.

Understanding the Shape: The “V” Is Intentional

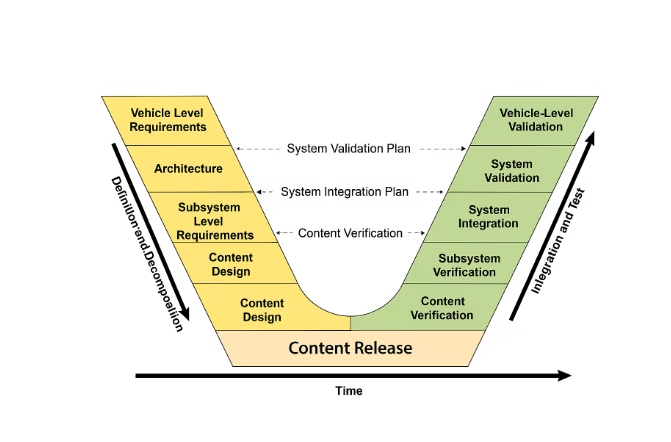

First, understand the shape. The “V” is not decorative; it encodes how work must converge.

Left arm — Definition and Decomposition. We define what the system must do, then break intent into system, subsystem, and component commitments.

Right arm — Integration and Test. We recompose the pieces and prove that execution matches intent through targeted verification and, at the top, validation.

Bottom point — Integration and Content Release. This stage serves as the reality checkpoint where defined commitments meet implementation. It is also where our adapted model places Content Release.

Therefore, the shape reminds teams that design decisions on the left drive the tests on the right, and both sides ultimately meet in reality at the bottom.

Commitment, Not Just Sequence

One of the most dangerous misconceptions is that the V-Model enforces a rigid, sequential process. In reality, each commitment on the left side is a declaration of intent, and that intent must later be proven on the right. Every requirement, every allocation, and every interface defined upstream is a promise the team is accountable for delivering.

This distinction is important. Time moves in a straight line, but validation does not. Verification unfolds only when each commitment is ready to be tested. Therefore, the V-Model functions as a structure of accountability, not a calendar.

Objectivist Lens: The V-Model as a Rational Structure

From an Objectivist standpoint, the V-Model reflects the virtues of clarity, integrity, and responsibility.

Metaphysics — The left side asks, “What is it?” This question grounds the system in metaphysics: we name what exists before attempting to create it.

Epistemology — The right side asks, “How do I know it works?” This is rational confidence built on verification, not assumption or hope.

Ethics — Every pairing in the V-Model shows the engineer’s responsibility to do the work correctly, not merely to finish it.

Seen this way, the V-Model becomes more than a compliance diagram. It acts as both a moral and operational tool, ensuring intent stays aligned with reality.

In later parts of this series, we will also examine how the remaining Objectivist branches—Politics (how a developed system is applied and governed) and Aesthetics (how purposeful design and elegance influence long-term performance)—further strengthen the V-Model’s role.

Each Commitment Has a Mirror

In the V-Model, every definition step on the left has a corresponding verification or validation step on the right. This symmetry is deliberate. For example:

Vehicle-level requirements connect directly to vehicle-level validation.

Subsystem requirements pair with subsystem verification.

Component design aligns with component verification.

This pairing ensures that nothing defined is left unproven. The mirror relationship also forces teams to plan verification and validation activities as they define requirements, rather than treating them as afterthoughts. Consequently, the model promotes discipline: you cannot declare a requirement complete until its mirror test is successfully executed.

This mirroring is not just symmetry—it’s accountability. Each verification or validation activity is the test of an earlier philosophical claim: “We committed that this system would do X.” Now prove it.

The adapted V-Model illustrates these mirrored commitments and their verification counterparts, including the “Content Release” point at the bottom.

The Bottom of the V: Where Reality Asserts Itself

The middle point—the integration and Content Release phase—is not just a handoff. It is the reality checkpoint, where defined commitments meet implementation.

This is the point where:

Undefined interfaces can break systems.

Ambiguous requirements collapse under their own uncertainty.

Gaps between intent and execution become fully visible.

Poor integration is rarely a surprise. It is almost always the consequence of misplaced or unclear commitments made earlier on the left side of the V. By linking this phase directly to Content Release in our adapted model, we make it clear that release is not the end of development. It is the decisive proof point for every commitment made upstream.

Why This Matters in the Real World

In fast-moving automotive programs, it can be tempting to skip the rigor of the left side of the V in favor of prototypes or quick demos. The thinking goes: “We’ll figure it out in test.”

However, the V-Model punishes vagueness. It rewards teams that define clearly, allocate requirements rigorously, and validate responsibly. When organizations skip formal requirement definition or fail to trace design intent to test cases, they often pay for it later through:

Post-launch issues

Regulatory failures

Warranty costs

Loss of customer trust

The V-Model is not bureaucracy for its own sake. It is engineering justice—a structure where reality holds every team accountable for the commitments they have made.

Closing Thought: Treat the V as a Contract with Reality

In conclusion, to embrace the V-Model is to acknowledge two truths: design is not real until it is validated, and intent is not valid until it is verified.

Consequently, You cannot declare success on the right side if you never made meaningful commitments on the left. Likewise, you cannot blame test results if you never defined what “working” means in the first place.

Therefore, the V-Model serves as both a technical framework and a moral contract—linking every design decision to a corresponding proof of performance.

Coming Up Next

Part 2: Requirement Cascades and the Illusion of Readiness

We will examine how shallow or recycled requirements lead to fragile systems—and how to use Objectivist metaphysics to anchor system definition in reality from the very start.

Furthermore, as the series progresses, we will map all five branches of Objectivist philosophy—Metaphysics, Epistemology, Ethics, Politics, and Aesthetics—onto the V-Model, showing how each contributes to building a complete framework for responsible systems engineering.

References

-

INCOSE Systems Engineering Handbook – Overview of systems engineering principles, including V-Model context

www.incose.org/products-and-publications/se-handbook -

ISO/IEC/IEEE 15288: System Life Cycle Processes – International standard defining system development and verification processes

www.iso.org/standard/63711.html - 3. ISO 26262: Road Vehicles – Functional Safety – Automotive functional safety standard where the V-Model is often applied

www.iso.org/standard/43464.html

References to Systems Engineering Series:

- What V-Model Really Means in Automotive Systems Engineering: https://georgedallen.com/what-v-model-really-means-in-automotive-systems-engineering/ <—You are here

- Requirement Cascades and the Illusion of Readiness: https://georgedallen.com/new-systems-engineering-avoiding-the-illusion-of-readiness/

- Bridging the Center – Integration as Reality Check: https://georgedallen.com/new-systems-engineering-v-model-supply-chain-alignment/

- Why the Right Side Fails – Verification Isn’t Testing: https://georgedallen.com/new-systems-engineering-v-model-risk-management/

- The Loop Within the V – Feedback and Continuous Learning: https://georgedallen.com/new-systems-engineering-the-loop-within-the-v-lifecycle-assurance/

- V-Model in the Real World – Politics, Timelines, and Design Drift: https://georgedallen.com/new-systems-engineering-v-model-in-the-real-world/

Systems Engineering References

About George D. Allen Consulting:

George D. Allen Consulting is a pioneering force in driving engineering excellence and innovation within the automotive industry. Led by George D. Allen, a seasoned engineering specialist with an illustrious background in occupant safety and systems development, the company is committed to revolutionizing engineering practices for businesses on the cusp of automotive technology. With a proven track record, tailored solutions, and an unwavering commitment to staying ahead of industry trends, George D. Allen Consulting partners with organizations to create a safer, smarter, and more innovative future. For more information, visit www.GeorgeDAllen.com.

Contact:

Website: www.GeorgeDAllen.com

Email: inquiry@GeorgeDAllen.com

Phone: 248-509-4188

Unlock your engineering potential today. Connect with us for a consultation.