Complexity Reduction: The New Concept of Simplification

Complexity Reduction: The New Concept of Simplification

Introduction: Why Complexity Reduction is a Necessity

Naturally, Complexity Reduction matters because complexity has a natural tendency to grow, and not all of it is necessary. Furthermore, some complexity is intentional, created to meet safety standards, enable new functions, or comply with regulations. However, other complexity adds no value. It enters quietly—through redundant features, overlapping requirements, or poorly coordinated changes—and then multiplies across the system. Over time, this unnecessary weight makes engineering harder, validation slower, and systems less reliable.

Therefore, the concept of Complexity Reduction addresses this problem directly. Complexity Reduction is the deliberate act of simplifying a system by removing what is unnecessary. It differs from related concepts such as Optimization, which seeks to improve the efficiency of a system as it stands. Where Optimization refines, Complexity Reduction eliminates. The discipline of Reduction asks: What can be removed without harming the system’s essential purpose?

In automotive engineering, this distinction is not abstract—it is decisive. Moreover, modern vehicles contain thousands of parts and millions of lines of code. Consequently, without Complexity Reduction, the verification burden grows unchecked. Without Optimization, performance stagnates. Therefore, both concepts matter, but Reduction is unique: it reshapes the structure itself, making systems easier to validate, safer to maintain, and more sustainable to scale into future programs.

Complexity Reduction vs. Optimization

Optimization is the concept of improvement within constraints. It accepts the current structure of the system and seeks to make it perform better. Optimization enhances speed, cost, or reliability, but the architecture remains the same: the same parts, the same interfaces, the same dependencies. Philosophically, Optimization treats complexity as an unavoidable reality.

Complexity Reduction, by contrast, is the concept of subtraction. It challenges whether existing structures are necessary at all. Rather than polishing the system as it stands, Reduction removes elements to simplify it outright. Fewer parts, fewer dependencies, and fewer interfaces mean fewer opportunities for propagation. Philosophically, Reduction treats complexity as a choice, not a given.

Furthermore, an example makes the difference clear. A platform may contain three separate ECUs—one for infotainment, one for navigation, and one for driver information. Optimization improves the software on each ECU, making them faster or more efficient, but leaves the triad intact. Complexity Reduction consolidates the three into a single domain controller, eliminating entire interfaces and reducing the need for integration testing. One concept refines complexity; the other prevents it.

In addition, in Systems Engineering, both concepts coexist. Optimization ensures performance in the short term. Complexity Reduction ensures sustainability in the long term. Without Optimization, systems underperform. Without Reduction, they collapse under their own weight.

Methods of Complexity Reduction

If Complexity Reduction is the concept, its methods are the tools. Hence, engineers must translate the idea of simplification into actions that reshape both technical systems and organizational structures. Several proven methods illustrate how Reduction becomes a discipline rather than an aspiration.

First, modularity. A modular design reduces complexity by creating stable, well-defined boundaries. Each module operates as a self-contained unit, limiting the number of direct dependencies. As a result, propagation slows because changes inside one module do not cascade unchecked across the system.

Second, standardization. Shared interfaces, common connectors, and consistent software libraries prevent unnecessary variation. Instead of multiplying unique requirements for each interface, standardization constrains them, reducing the number of cases to be verified. In automotive practice, standardized communication protocols or connector types often deliver large reductions in validation effort.

Third, reuse and carry-over. Complexity multiplies when teams constantly reinvent solutions. By reusing validated parts and systems, engineers avoid creating fresh layers of requirements. Reuse not only reduces workload but also builds trust in proven designs.

Fourth, elimination of redundancy. Over time, systems accumulate overlapping features or duplicate requirements. Careful review often reveals functions that can be pruned without harming performance. Each removal reduces the network of interfaces and the associated validation burden.

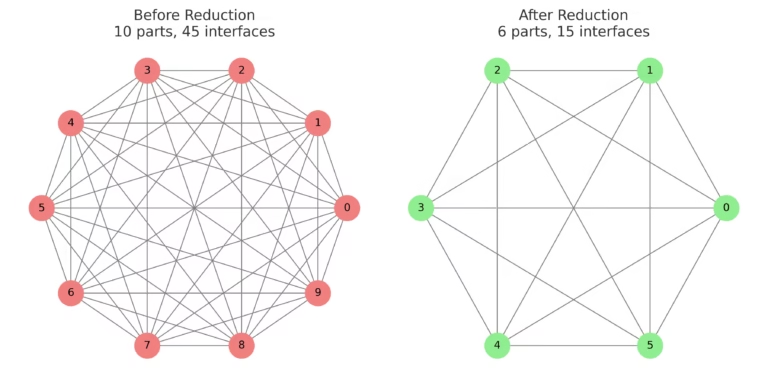

Finally, architectural simplification. The structure of the system matters most. Moving from dense, fully connected meshes to hierarchical or zonal architectures cuts interface counts dramatically. For instance, replacing dozens of distributed ECUs with a handful of zonal controllers reduces not only part count but also thousands of potential interactions.

Together, these methods show that Reduction is not a single action but a discipline. Each choice—modularity, standardization, reuse, elimination, or simplification—applies the concept in practice, allowing engineers to manage growth before it overwhelms the system.

Quantifying Reduction

Essentially, to practice Complexity Reduction as more than an idea, engineers must measure its effect. Therefore, without quantification, simplification risks becoming subjective. Hence, metrics allow teams to compare before and after, proving that Reduction delivers tangible value.

The first measure is part count. Fewer components usually mean fewer opportunities for faults, propagation, and integration effort. Reducing part count by even ten percent often produces a larger drop in validation workload because each removed component also eliminates its interfaces.

The second measure is interface count. Since interfaces drive exponential growth, every reduction matters. For example, a system with 100 parts has 4,950 potential interfaces. Cutting the design to 70 parts lowers the number of potential interfaces to 2,415—less than half. The effect is not linear; it is multiplicative.

The third measure is requirement count. Each part and each interface introduces requirements. When Reduction removes elements, it removes their requirements as well. Verification and validation lists shrink in proportion. A simpler architecture translates directly into a lighter test burden.

The fourth measure is verification load. Test cases are the most visible cost of complexity. By tracking how many tests can be retired through Reduction, engineers connect simplification to program schedules and budgets. In practice, fewer tests mean faster integration and earlier launches.

Additionally, quantification also helps align organizations. Executives respond to numbers; suppliers respond to measurable targets. Therefore, when engineers present part counts, interface counts, and test counts as evidence, Reduction gains credibility as a strategy, not just a philosophy.

Ultimately, quantifying Reduction makes it a discipline. Furthermore, by turning simplification into measurable progress, teams ensure that Complexity Reduction does not remain an abstract concept but becomes an operational practice.

Visual Aid – Complexity Reduction – Before and After

This diagram illustrates how Complexity Reduction reshapes a system. Firstly, on the left, ten parts form forty-five interfaces, creating a dense network of dependencies. Followed by. on the right, six parts form only fifteen interfaces, a structure that is easier to manage and validate. Obviously, the reduction is not linear: removing four parts eliminates thirty connections. This demonstrates the compounding benefit of simplification—fewer parts lead to far fewer requirements, far fewer tests, and far less opportunity for propagation.

Engineering Practices for Complexity Reduction

The concept of Complexity Reduction becomes real only when supported by consistent practices. These practices guide engineers in deciding what to remove, what to reuse, and how to prevent unnecessary complexity from creeping back into the system.

First, impact analysis. Every proposed change should be traced through its possible effects. Impact analysis highlights which parts and interfaces carry the greatest ripple potential. By identifying high-leverage elements, teams can focus Reduction efforts where they matter most.

Second, change control. Formal boards and structured reviews may appear to slow projects, but they exist to prevent unnecessary additions. A disciplined change process asks whether a proposed feature justifies the complexity it introduces. Many systems grow not through major decisions but through unchecked accumulation of small changes.

Third, lessons learned. Past projects often reveal where complexity became unmanageable. Capturing and applying these lessons prevents teams from repeating avoidable mistakes. A well-used lessons-learned database acts as a brake on runaway growth.

Fourth, peer review. External perspectives expose over-engineered solutions. A subsystem designed with redundant features or overly tight tolerances may look elegant to its creators, but a review team can recognize opportunities for simplification.

Finally, simulation. Working models developed in parallel with hardware allow engineers to test where complexity builds unnecessarily. Simulations can reveal redundant requirements or overlapping interfaces before they solidify into physical designs. Correlated outputs between simulation and validation make these insights credible.

Together, these practices turn Reduction into a repeatable process. They ensure that simplification is not left to intuition or last-minute fixes but is built into the engineering lifecycle from the start.

Automotive Examples of Complexity Reduction

Generally, the concept of Complexity Reduction is not abstract—it already shapes modern vehicle programs. Furthermore, several examples from the automotive industry show how deliberate simplification delivers measurable results.

Zonal architectures. Traditional vehicles rely on dozens of distributed ECUs scattered across the vehicle. Each ECU adds parts, wiring, and interfaces. Zonal architectures replace this sprawl with a handful of zone controllers, each responsible for a region of the car. The result is fewer ECUs, fewer connectors, and a dramatic reduction in wiring complexity.

Sensor suite consolidation. Advanced Driver Assistance Systems (ADAS) once relied on separate sensors for each function—one camera for lane keeping, another for traffic sign recognition, another for driver monitoring. Today, OEMs increasingly consolidate functions into shared sensors. One high-resolution camera can support multiple algorithms, reducing both part count and integration testing.

Battery pack standardization. Electric vehicle programs often begin with multiple module types tailored to different variants. Over time, leading OEMs reduce this variety by standardizing module design and simplifying thermal management approaches. Fewer variants mean fewer validation cases, fewer supply chain risks, and lower cost.

Feature rationalization. Infotainment systems illustrate how features accumulate unchecked. Two overlapping apps may compete to deliver navigation or media playback, confusing the customer and doubling the validation work. Rationalization eliminates duplication, leaving a cleaner and more intuitive system for both users and engineers.

Basically, each example demonstrates the same principle: simplification multiplies its benefits. By reducing parts and interfaces, OEMs not only cut costs but also accelerate validation and reduce the risk of propagation. Complexity Reduction turns into an enabler of safety, speed, and clarity.

Organizational Complexity Reduction

Overall, complexity does not reside only in technical systems. Organizations themselves accumulate it—through structures, processes, and communication paths. Therefore, the concept of Complexity Reduction applies as much to people and processes as it does to parts and interfaces.

Simplifying structures. Large programs often create layers of management, committees, and checkpoints. Each new layer adds overhead and slows decision-making. Reduction in this context means flattening structures, clarifying accountability, and ensuring that decisions flow directly to those who implement them.

Streamlining communication. The more teams that must coordinate, the greater the risk of misalignment. By reducing unnecessary handoffs and clarifying points of contact, organizations prevent ripples from becoming bottlenecks. Cross-functional alignment becomes simpler when pathways are fewer.

Supplier consolidation. Technical complexity often mirrors organizational complexity. Managing dozens of suppliers across overlapping domains multiplies dependencies. Consolidating suppliers—fewer but deeper partnerships—reduces interfaces at both the technical and organizational level.

Cultural shift. Perhaps the hardest reduction is cultural. Many organizations reward adding features, structures, or processes, but rarely reward removing them. Embracing Complexity Reduction as a value means recognizing simplicity as strength, not as a lack of ambition. It requires leaders to ask: Does this structure, process, or feature truly serve the purpose?

Moreover, when organizations apply Reduction to themselves, they gain clarity. Teams move faster, communication improves, and suppliers align more tightly with program goals. Just as in technical systems, fewer moving parts in organizations mean fewer opportunities for propagation to spread.

Conclusion: The Discipline of Simplification

In conclusion, complexity grows naturally, but reduction requires conscious choice. Therefore, the concept of Complexity Reduction is not about cutting corners or removing capability—it is about stripping away what does not serve the system’s purpose. Furthermore, by focusing on essentials, engineers design architectures that are easier to verify, simpler to maintain, and more resilient in operation.

Additionally, throughout this chapter, we have treated Reduction as a discipline: a set of methods, practices, and organizational habits that prevent complexity from overwhelming programs. Moreover, modularity, standardization, reuse, elimination of redundancy, and architectural simplification demonstrate how the concept applies in practice. Consequently, quantification provides the evidence: fewer parts, fewer interfaces, and fewer tests translate directly into leaner, safer systems. Hence, automotive examples confirm that simplification is not only possible but already shaping vehicle platforms, from zonal architectures to sensor consolidation. As evidence. even organizations themselves benefit from the same principle when they flatten structures, streamline communication, and consolidate suppliers.

Finally, the key insight is that Complexity Reduction differs fundamentally from Optimization. Optimization improves what exists; Reduction questions whether it should exist at all. Both concepts are necessary. Without Optimization, systems underperform. Without Reduction, they collapse under their own weight.

As engineers, we cannot prevent complexity from appearing. But we can practice the discipline of simplification, challenging every addition to prove its necessity. In doing so, we not only reduce cost and risk—we reclaim clarity.

The next chapter turns to Optimization, exploring how systems can be refined once unnecessary complexity has been removed. Where Reduction clears the ground, Optimization builds on what remains. Together, they form complementary disciplines for managing modern engineering.

References

-

INCOSE Systems Engineering Handbook – Overview of systems engineering principles, including V-Model context

www.incose.org/products-and-publications/se-handbook -

ISO/IEC/IEEE 15288: System Life Cycle Processes – International standard defining system development and verification processes

www.iso.org/standard/63711.html - 3. ISO 26262: Road Vehicles – Functional Safety – Automotive functional safety standard where the V-Model is often applied

www.iso.org/standard/43464.html

References to Complexity in Systems Engineering Series:

- What Do We Mean by Complexity?

- The Growth of Complexity

- Counting Complexity – Why Interfaces Grow Faster Than Parts

- Propagation: How Complexity Spreads

- Complexity Reduction: The Discipline of Simplification <—You are here

- Optimization: Improving the Existing System

- Requirements: The First Line of Defense

- Measuring and Managing Complexity

- From ppm to ppb – The Statistical Reality of Vehicle Defects

- Complexity in Practice: Case Studies & Critiques

Simulation and Virtual Models – Managing Complexity in Verification and Validation

Systems Engineering References

About George D. Allen Consulting:

George D. Allen Consulting is a pioneering force in driving engineering excellence and innovation within the automotive industry. Led by George D. Allen, a seasoned engineering specialist with an illustrious background in occupant safety and systems development, the company is committed to revolutionizing engineering practices for businesses on the cusp of automotive technology. With a proven track record, tailored solutions, and an unwavering commitment to staying ahead of industry trends, George D. Allen Consulting partners with organizations to create a safer, smarter, and more innovative future. For more information, visit www.GeorgeDAllen.com.

Contact:

Website: www.GeorgeDAllen.com

Email: inquiry@GeorgeDAllen.com

Phone: 248-509-4188

Unlock your engineering potential today. Connect with us for a consultation.